The Cause of the CP4 Failures: Lack of Lubricity in the Fuel

Ultra-Low Sulfur Diesel (#2 Diesel) = Ultra-Low Lubricity Diesel.

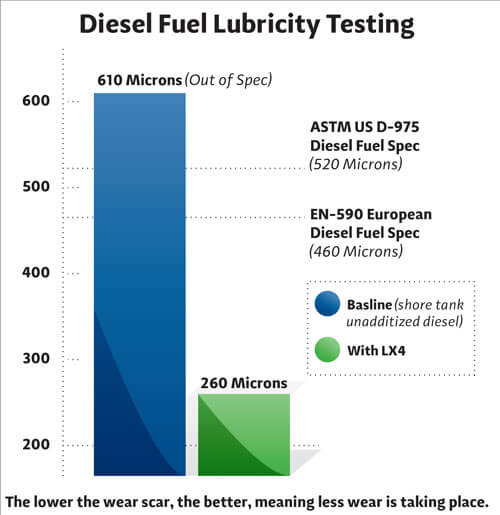

Today’s Ultra-Low Sulfur Diesel (ULSD) does not contain the lubricity needed to fully protect our vehicles. The Bosch CP4 fuel pump has an unusually high failure rate in the U.S., upwards of 7%, when compared to 1% failure rate in Europe. So why is the failing CP4 being installed in so many vehicles? When leaving the manufacturer the CP4 pump is typically successful because the pump is manufactured in Europe. The difference between the USA and Europe is that the lubricity properties have not been removed from the European diesel fuel, as it has in the U.S. fuel. The European EN-590 diesel fuel has a wear scar diameter 460-micron specification while in the U.S. the base is 520-micron in ASTM US D-975. Therefore, the failure is caused by the lack of lubricity in ultra-low sulfur fuel in the USA.

More so, the failure is the lack of the proper additives used to supplement fuel degradation and the ability to restore the lubricity that is easily available. For those that have gone without these fuel lubricity components and simply relied on the untreated fuel, yes, the lack of lubricity in ULSD fuel has caused the breakdown. With one extra step, however, by adding the correct fuel additive, lubricity can be restored, and the pump will operate in a similar circumstance as originally manufactured in Europe.

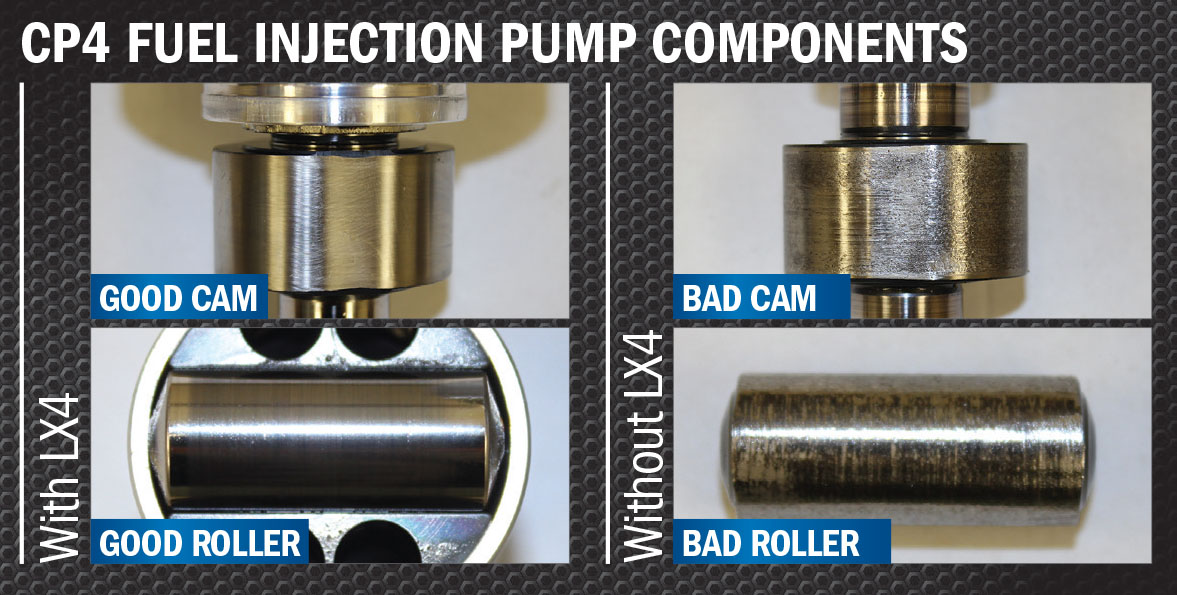

The lack of lubricity in ULSD is the main factor in the catastrophic failures of the CP4 Fuel pumps. High rates of wear from lack of lubricity can introduce metal shavings into the fuel system. These metal shavings create wear that damages your injectors, cylinder walls, pistons, and rings costing several thousands of dollars to repair.

The CP4 Failure Defined:

In an attempt to improve fuel efficiency, the CP4 injection pump replaced the CP3 pump to create a higher-pressure expulsion with less fuel volume consumed.

With the lack of ability to supply the adequate fuel needed, thereby also reducing the amount of lubrication to the system, the CP4 forms air bubbles inside the injectors. When air is within the system, there is no fuel. Where there is no fuel there is no lubrication. Where there is no lubrication, there is instead metal on metal friction, causing accelerated wear and components to fail.

During the degradation of the parts, metal shavings are traveling through the entire fuel system, including the fuel injectors and the fuel lines thereby causing more friction and abrasive compounds throughout the travel of the fuel.

The attempt to reduce fuel consumption is a compounded effect of low-quality fuel with less sulfur lubricity, and then less of the fuel itself. The double negative is a direct reduction of lubricity in the system.